| The article below, the first of a

series of three, was written for us by

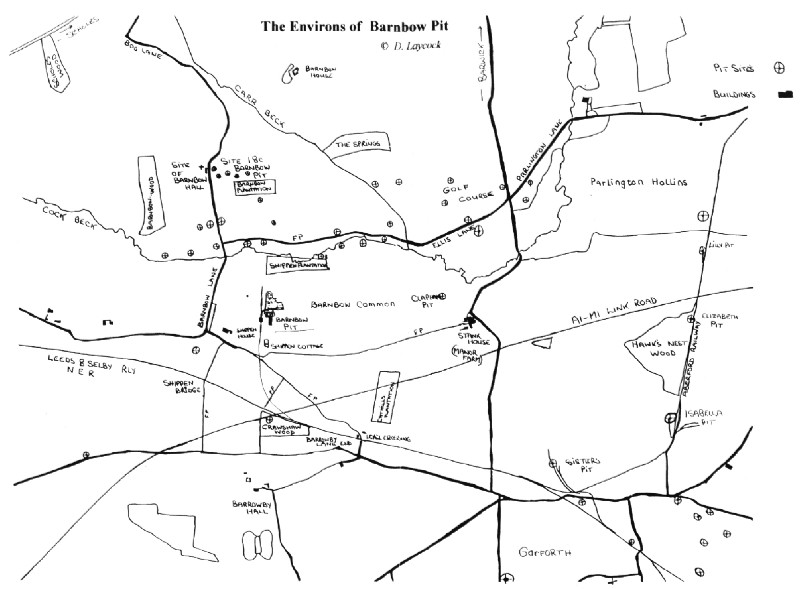

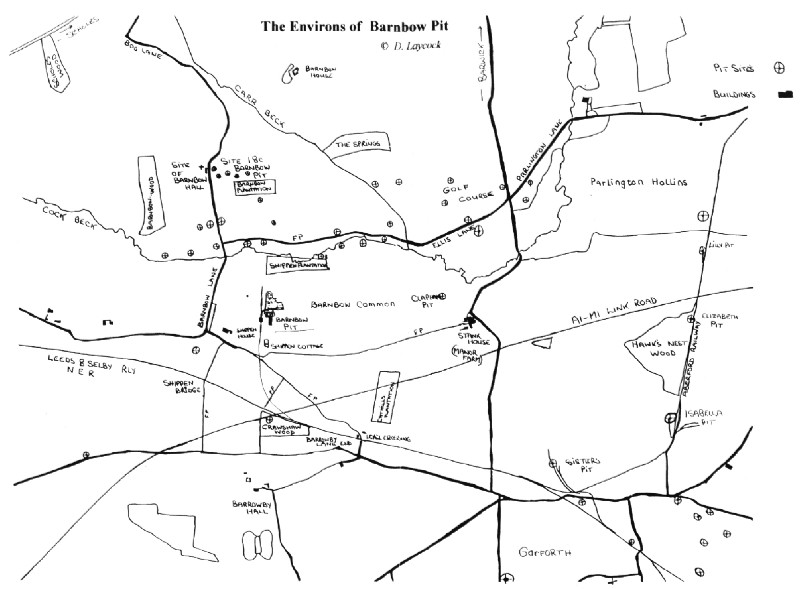

Douglas Laycock of Garforth. He has for many

years researched the histories of the Shell

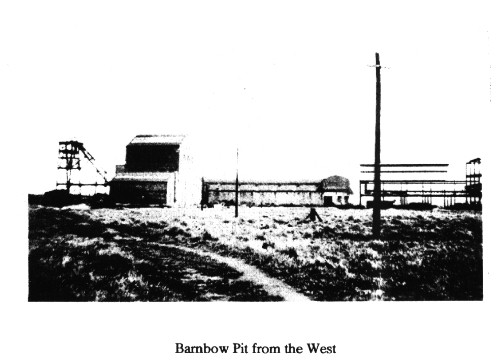

Filling Factory at Barnbow and also the

Barnbow Pit, about which little has been

previously published. |

| Douglas is a good friend of the Historical Society, who spoke on these topics at one of our meetings several years ago and led us round the sites on one of our summer outings. He also gave much help in the writing of the article by Tony Cox on The Barnbow Shell Filling Factory (see 'The Barwicker' No. 47). We thank Douglas most sincerely for his articles. |

| DOUGLAS LAYCOCK |