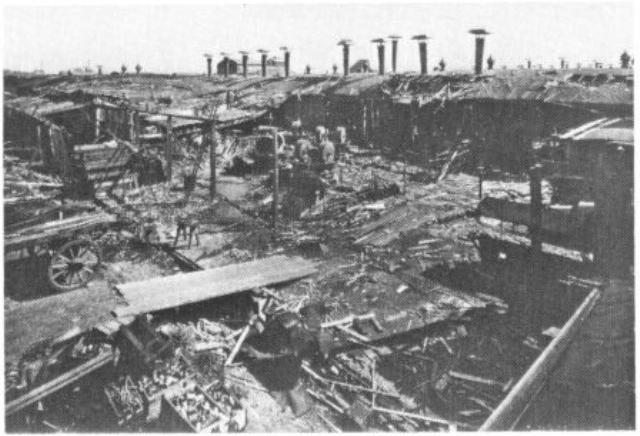

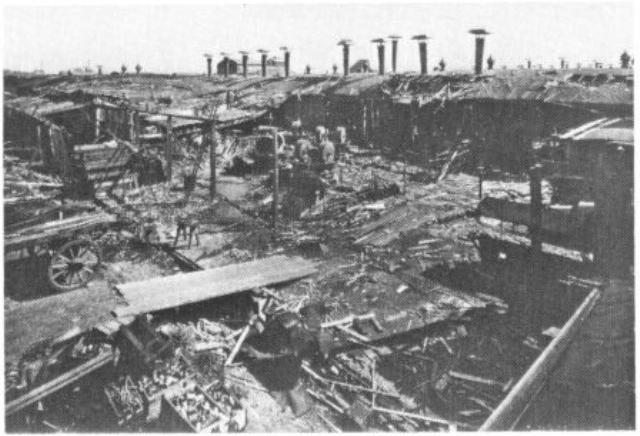

The effect of the explosion on the 31st May 1918