|

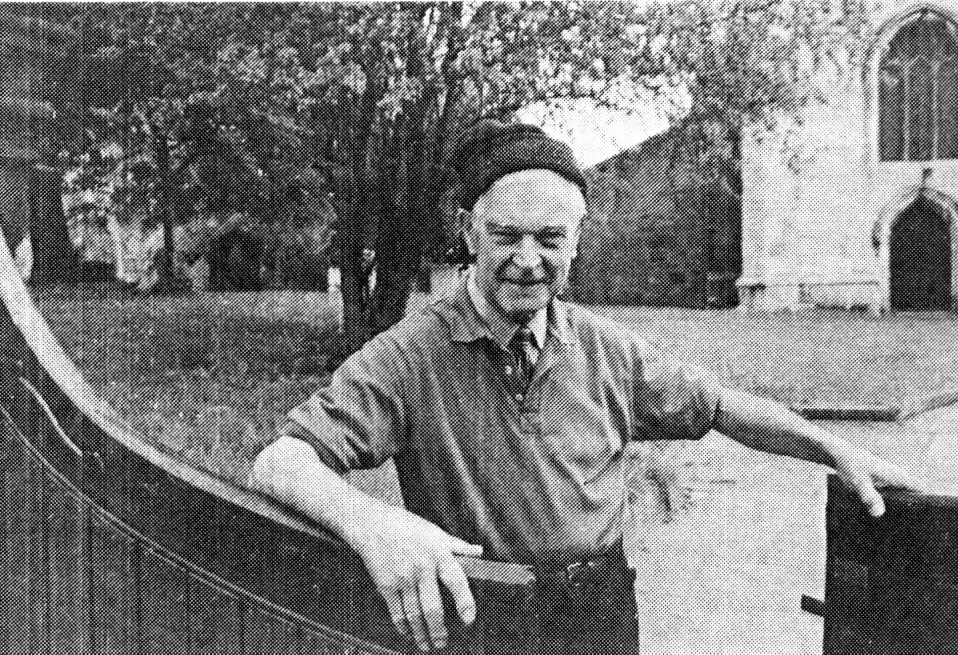

"Tony Shinn, the writer of this article, who used the skills

he learned in the wheelwright's shop to repair the church gates" |

|

"Tony Shinn, the writer of this article, who used the skills

he learned in the wheelwright's shop to repair the church gates" |

TONY SHINN |